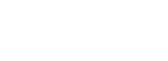

Compaction grouting is a powerful ground improvement technique used to stabilize soils, increase load-bearing capacity, and reduce settlement risks. It’s widely employed in geotechnical engineering projects, including building foundations, infrastructure development, and sinkhole remediation. But what is the science behind compaction grouting, and how does it achieve these transformative effects on the ground? Let’s delve into the process and principles at work.

What is Compaction Grouting?

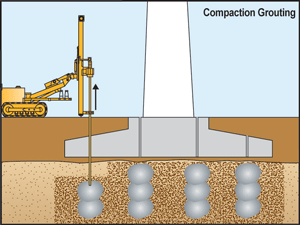

Compaction grouting involves injecting a low-mobility, high-viscosity grout into the ground under pressure. Unlike other grouting methods that flow through soil pores, compaction grouting forms a dense bulb at the injection point. As the grout bulb expands, it displaces and compresses the surrounding soil, improving its density and strength.

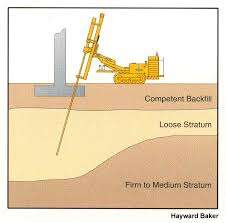

This method is highly effective for addressing weak or loose soils, such as sands, silts, or fill materials, which may compromise the stability of overlying structures.

The Scientific Principles at Work

1. Stress Transfer and Soil Compaction

When grout is injected, it exerts a lateral pressure on the surrounding soil. This pressure compresses the soil particles, increasing their density and reducing void spaces. The mechanism relies on the principle of stress transfer, where the force applied by the expanding grout bulb radiates outward, compacting the soil in the process.

2. Soil Mechanics and Densification

The degree of improvement depends on soil type and initial density. Loose soils experience significant compaction, as the void ratio decreases, and interparticle friction increases. In contrast, denser soils experience minimal changes because their particles are already tightly packed.

3. Controlled Plastic Deformation

Compaction grouting relies on plastic deformation rather than fracturing. The pressure from the grout must be high enough to displace soil particles without exceeding their shear strength. If the pressure is too high, the soil may fracture, reducing the effectiveness of the process.

Advantages of Compaction Grouting

- Precision: The grout can be injected at specific depths and locations for targeted improvement.

- Versatility: It works for various soil types, including weak and loose fill materials.

- Load-Bearing Improvement: By compacting soil, this method significantly enhances its load-bearing capacity.

- Minimized Disruption: Compaction grouting typically requires minimal excavation, reducing construction downtime.

Applications of Compaction Grouting

1.Foundation Stabilization

Compaction grouting strengthens weak soils under existing structures, preventing settlement and ensuring long-term stability.

2.Sinkhole Remediation

In regions prone to sinkholes, this technique is used to fill voids and compact surrounding soil to prevent collapse.

3.Seismic Retrofits

In earthquake-prone areas, compaction grouting helps mitigate liquefaction risks by densifying sandy soils.

4.Pipeline Support

Compaction grouting provides additional support to pipelines or other underground utilities to prevent movement or settlement.

Conclusion

Compaction grouting is a sophisticated technique rooted in the principles of soil mechanics and stress transfer. By precisely injecting high-viscosity grout, engineers can compact and strengthen loose soils, transforming weak ground into a stable foundation. Whether for stabilizing structures, remediating sinkholes, or preparing for seismic resilience, compaction grouting continues to play a critical role in modern geotechnical engineering.