Introduction

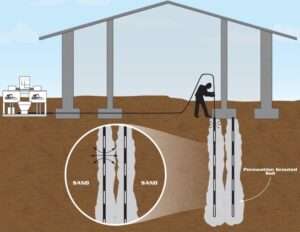

Tube-à-Manchette (TAM) grouting is an advanced soil treatment technique used for ground stabilization, waterproofing, and structural reinforcement. This method involves injecting grout through specialized perforated tubes to improve soil strength and reduce permeability. TAM grouting is widely used in tunneling, deep excavations, dam foundations, and infrastructure projects requiring precise ground modification.

1.Understanding TAM Grouting

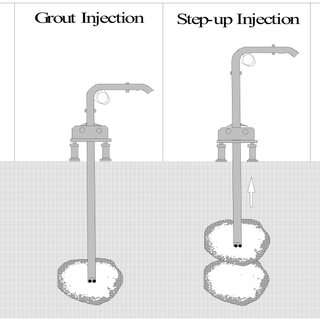

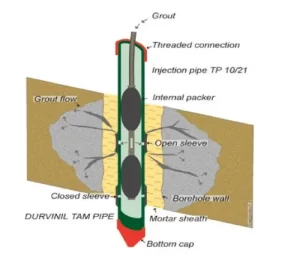

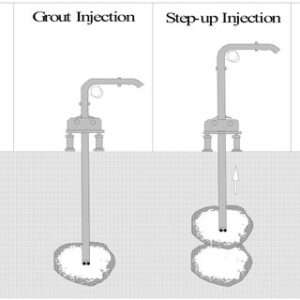

TAM grouting is a controlled injection process where grout is delivered through pre-installed sleeve pipes (Tube-à-Manchette) into the surrounding soil or rock. The grouting process is executed in stages, allowing for targeted treatment and minimizing disturbance to adjacent structures.

Key Components of TAM Grouting:

- Sleeve Pipes (Tubes-à-Manchette) – Perforated pipes with rubber sleeves installed in boreholes.

- Grout Injection System – A pressure-controlled system for delivering grout to desired depths.

- Injection Phases – Grout is injected in multiple stages to ensure uniform soil treatment.

2.Applications of TAM Grouting

TAM grouting is a versatile solution used in various engineering applications:

- Ground Stabilization – Strengthening weak or loose soil for foundation support.

- Seepage Control – Reducing groundwater flow in tunnels, basements, and dam foundations.

- Structural Underpinning – Reinforcing existing foundations to prevent settlement.

- Cavity and Void Filling – Treating underground voids in karst formations or old mine workings.

- Slope and Embankment Reinforcement – Preventing soil erosion and landslides.

3.Types of Grout Used in TAM Grouting

Different grout materials are selected based on soil conditions and project requirements:

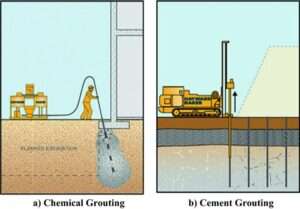

- Cementitious Grout – Common for structural reinforcement and filling voids.

- Chemical Grout – Expanding polyurethane or silicate-based solutions for waterproofing and soil stabilization.

- Bentonite Grout – Used for permeability reduction in water-bearing soils.

4.Advantages of TAM Grouting

Targeted Soil Treatment – Allows precise delivery of grout to problem areas.

Minimal Ground Disturbance – Does not require extensive excavation.

Enhanced Load-Bearing Capacity – Strengthens soil to support heavy structures.

Waterproofing Benefits – Effectively seals underground structures from water infiltration.

Versatile for Various Soil Types – Suitable for sands, silts, clays, and fractured rock.

5.Challenges and Considerations

Requires Specialized Equipment and Expertise – Precise injection control is essential.

Higher Cost Compared to Traditional Grouting – Due to staged injection and monitoring.

Grout Flow Control Limitations – Difficult to predict grout spread in highly permeable soils.

6.Innovations in TAM Grouting

- Automated Grouting Systems – Improve accuracy and efficiency in injection control.

- Real-Time Monitoring with Sensors – Allows data-driven adjustments during grouting.

- Eco-Friendly Grout Materials – Reducing environmental impact with sustainable alternatives.

Conclusion

TAM grouting is a highly effective technique for ground stabilization, structural support, and waterproofing. Its precision and adaptability make it a preferred choice in complex geotechnical projects where traditional methods fall short. As technology advances, TAM grouting continues to evolve, offering even greater efficiency, sustainability, and performance in soil treatment and foundation engineering.