In the world of geotechnical engineering, self-drilling anchors (SDAs) have emerged as a game-changing solution for slope stabilization and ground support. Combining drilling, grouting, and anchoring into a single streamlined process, SDAs have revolutionized the way engineers approach challenging terrain, construction projects, and soil stabilization.

Understanding Self-Drilling Anchors

Self-drilling anchors are specialized systems consisting of a hollow bar with a sacrificial drill bit at the tip. They enable simultaneous drilling and grouting, which simplifies the installation process, reduces labor costs, and accelerates project timelines. The anchor rod is designed to remain in the ground and serve as reinforcement after installation.

Key Advantages of Self-Drilling Anchors

1.Efficient Installation Process

SDAs eliminate the need for pre-drilled holes, as they can drill directly into soil, rock, or mixed ground conditions. This makes them particularly effective for projects where time and accessibility are critical factors.

2.Versatility in Challenging Conditions

Traditional anchoring methods often struggle with unstable ground, fractured rock, or water-saturated soils. Self-drilling anchors overcome these limitations by combining the drilling and grouting process, ensuring a secure and robust anchor even in the most difficult environments.

3.Time and Cost Savings

By integrating multiple steps into a single process, SDAs reduce labor, equipment usage, and project durations, resulting in significant cost savings for both small and large-scale projects.

4.Enhanced Stability and Load Capacity

The grouting process fills voids, strengthens surrounding soil, and protects the anchor from corrosion, enhancing its stability and load-bearing capacity.

Applications of Self-Drilling Anchors

Self-drilling anchors are widely used across various industries due to their adaptability and reliability:

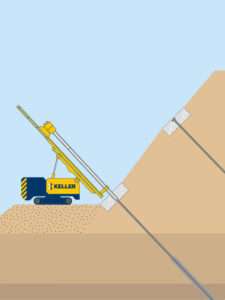

- Slope Stabilization: SDAs are extensively employed to stabilize natural and man-made slopes, preventing landslides and erosion in infrastructure projects.

- Tunneling and Underground Support: In tunnel construction, SDAs provide essential ground reinforcement, reducing risks of collapses and enhancing structural integrity.

- Foundation Support: They are used as micropiles to reinforce foundations in difficult soil conditions or to retrofit existing structures.

- Mining and Excavation: Self-drilling anchors ensure ground support in mines and excavations, improving safety and productivity in these high-risk environments.

How Self-Drilling Anchors Work

The installation of self-drilling anchors involves four key stages:

1.Drilling: The hollow anchor bar, equipped with a drill bit, is driven into the ground using rotary percussion drilling.

2.Grouting: Cementitious grout is injected through the hollow bar during or after drilling, filling voids and solidifying the surrounding material.

3.Reinforcement: Once the grout sets, the hollow bar remains embedded in the ground as a load-bearing reinforcement element.

4.Anchoring: The anchor is tensioned and secured to ensure stability and load transfer.

Why Self-Drilling Anchors Are the Future

As infrastructure projects continue to face increasingly complex terrain and soil conditions, the demand for reliable, efficient, and cost-effective ground support systems grows. Self-drilling anchors offer a versatile and innovative solution that meets these demands, making them indispensable tools for modern geotechnical engineering. Their ability to handle difficult environments, save time, and reduce costs ensures that SDAs will remain at the forefront of slope stability and ground reinforcement technologies.

In conclusion, self-drilling anchors are revolutionizing the construction industry by simplifying processes, enhancing safety, and providing dependable solutions for challenging ground conditions. From stabilizing slopes to supporting tunnels and foundations, SDAs are paving the way for stronger, safer, and more resilient infrastructure projects worldwide.