Self-drilling anchors (SDAs) play a crucial role in ground reinforcement, especially in construction, mining, and geotechnical engineering. These specialized anchors are designed to stabilize loose or unstable ground conditions, offering support in tunnels, foundations, and various civil engineering projects. In this comprehensive guide, we’ll explore how self-drilling anchors work, their advantages, applications, installation process, and why they are essential for ground reinforcement.

What Are Self-Drilling Anchors?

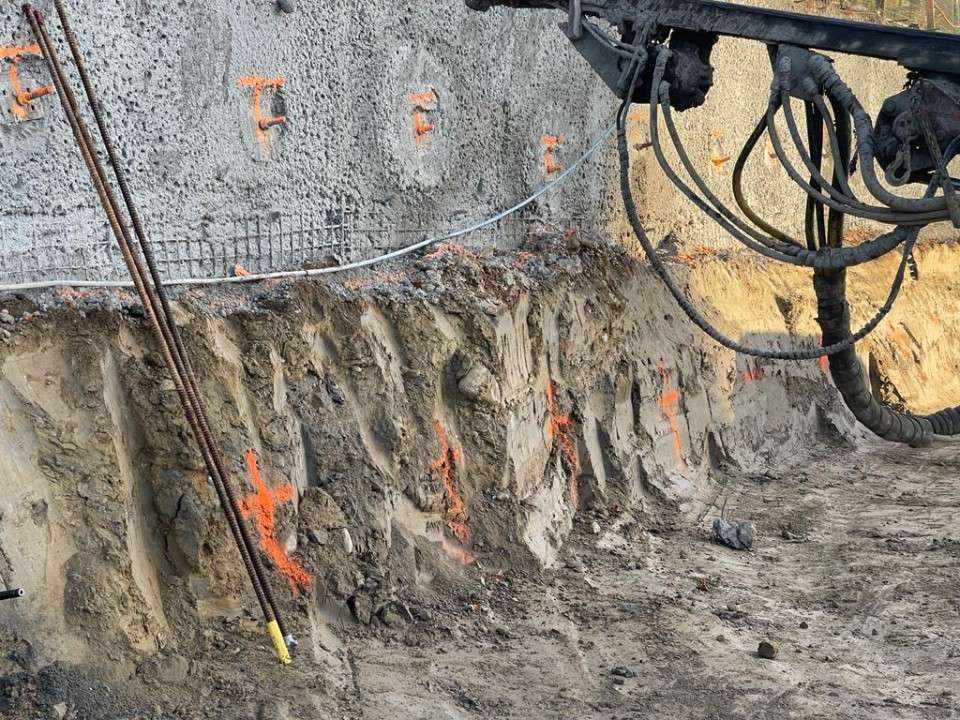

Self-drilling anchors are a type of anchoring system that can drill and anchor into the ground simultaneously. They are typically composed of a hollow steel bar, a sacrificial drill bit, couplers, and a nut and plate for additional support. The hollow bar allows for simultaneous drilling and grouting, enabling SDAs to be highly efficient in unstable soils or rock formations where traditional anchoring methods may fail.

The anchor’s ability to both drill and stabilize in a single operation eliminates the need for casing in loose ground, which makes the process quicker, safer, and more cost-effective.

How Do Self-Drilling Anchors Work?

Self-drilling anchors combine drilling and anchoring into one system. Here’s a step-by-step breakdown of how they work:

- Drilling Phase: The self-drilling anchor system starts with the installation of a sacrificial drill bit at the tip of the hollow bar. When rotated by a drill rig, the bit cuts into the soil or rock while simultaneously creating a passage for the bar.

- Grouting Phase: Grout (typically a cementitious mixture) is pumped through the hollow center of the bar as it is drilled into the ground. The grout fills the hollow shaft and the surrounding hole, providing structural integrity and bond strength to the anchor. It also stabilizes loose material, preventing collapse or movement.

- Reinforcement Phase: Once the anchor is installed and grouted, it hardens to provide long-term reinforcement. The nut and plate installed at the top of the anchor help distribute the load and maintain tension.

This method ensures that the ground is reinforced both immediately and long-term, allowing for safe and stable construction in challenging conditions.

Key Advantages of Self-Drilling Anchors

Self-drilling anchors offer several advantages over traditional methods of ground stabilization:

- Time-Efficient: The simultaneous drilling and grouting reduce the number of installation steps, significantly cutting down on labor and project duration.

- Versatile: SDAs can be used in a wide range of soil and rock conditions, including loose soils, gravel, sand, clay, and fractured rock. Their ability to self-drill through various substrates makes them adaptable to different geotechnical environments.

- Cost-Effective: Since no casing is required, and installation time is reduced, self-drilling anchors can save on both material and labor costs.

- Improved Safety: The rapid installation process and the ability to stabilize weak ground immediately enhance overall site safety, especially in projects involving tunneling and excavation.

- High Load Capacity: These anchors are capable of bearing high loads, making them ideal for large-scale construction projects and heavy-duty applications.

Applications of Self-Drilling Anchors

Self-drilling anchors are utilized in a variety of sectors where ground reinforcement is required, including:

- Tunneling: SDAs are used to stabilize tunnel walls and prevent collapses, particularly in loose ground or fractured rock formations.

- Foundations: They are employed in foundation systems to improve the stability of buildings and structures built on unstable or loose ground.

- Slope Stabilization: In geotechnical engineering, SDAs reinforce slopes, preventing landslides and erosion in hilly or mountainous terrains.

- Mining: Underground mining operations rely on self-drilling anchors to ensure the safety of miners and equipment by reinforcing tunnel walls and ceilings.

- Retaining Walls: In civil engineering, SDAs are often used in the construction of retaining walls to provide additional support and prevent soil displacement.

Installation Process

The installation of self-drilling anchors involves several key steps:

- Drill Rig Setup: A drill rig is positioned at the installation site. The hollow steel bar is connected to a sacrificial drill bit.

- Drilling and Grouting: The bar, with its drill bit, is rotated and drilled into the ground. Grout is pumped through the hollow shaft as drilling progresses, filling the surrounding void.

- Anchor Positioning: The anchor is drilled to the desired depth and left to harden in place as the grout cures.

- Tensioning: Once the grout is set, the nut and plate are installed at the surface to apply tension and ensure that the anchor remains under load.

- Final Inspection: After installation, the anchors are inspected and tested for load-bearing capacity and correct placement.

Why Self-Drilling Anchors Are Essential for Ground Reinforcement

Ground reinforcement is critical in construction, mining, and geotechnical projects where the stability of the surrounding terrain is compromised. Self-drilling anchors offer a reliable, efficient, and cost-effective solution, making them a popular choice in environments where traditional methods might fail. Their ability to reinforce weak soils, fractured rock, and unstable ground provides peace of mind to engineers and contractors alike.

In summary, self-drilling anchors are an invaluable tool in modern construction and geotechnical projects. Their versatility, ease of installation, and strong load-bearing capacity make them an ideal solution for ground reinforcement in even the most challenging conditions. Whether stabilizing tunnels, slopes, foundations, or retaining walls, SDAs ensure long-term structural integrity and safety.