Secant piles are a highly effective and versatile solution in geotechnical engineering, offering robust support for excavations and effective groundwater control. These interlocking piles create a continuous wall that resists lateral soil pressure and water ingress, making them ideal for challenging sites, including urban areas and regions with high water tables. Their adaptability and performance make them a go-to option for complex construction projects.

What Are Secant Piles?

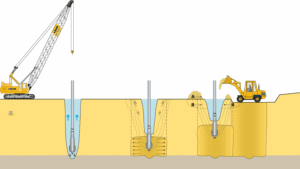

Secant piles are constructed by alternating primary and secondary piles, where primary piles are typically unreinforced, and secondary piles are reinforced with steel or concrete. The secondary piles overlap the primary piles, forming a watertight or near-watertight interlocking wall. This overlapping design enhances the wall’s strength and impermeability.

Applications of Secant Piles

1.Excavation Support:

Provide lateral support for deep excavations in urban settings, minimizing the risk of soil collapse.

Commonly used in basements, tunnels, and underground stations.

2.Groundwater Control:

Act as a cutoff wall to prevent groundwater flow into excavations.

Essential in high water table areas to maintain site stability.

3.Slope Stabilization:

Stabilize slopes in landslide-prone areas, reducing the risk of soil erosion and movement.

4.Retaining Structures:

Used as permanent retaining walls for infrastructure projects like bridges and highways.

Advantages of Secant Piles

- High Strength:

- Overlapping piles create a strong, continuous wall capable of resisting significant lateral loads.

- Effective Water Barrier:

- Interlocking design minimizes water seepage, ideal for groundwater control.

- Versatility:

- Applicable in various soil conditions, including soft clays, sands, and gravels.

- Space Efficiency:

- Suitable for constrained sites where traditional excavation methods are impractical.

- Durability:

- Reinforced secondary piles ensure long-term structural performance.

Design and Construction Process

1.Site Assessment:

Conduct geotechnical investigations to evaluate soil properties, groundwater levels, and load requirements.

2.Pile Layout:

Determine the spacing, diameter, and overlap of primary and secondary piles.

3.Drilling and Installation:

Drill boreholes for primary piles and fill them with unreinforced concrete.

Drill secondary piles to overlap the primary piles and insert reinforcement before concreting.

4.Finishing:

Apply surface treatments or cladding if the wall will be exposed.

Challenges and Mitigations

- Precision Alignment:

- Overlapping piles require accurate drilling to ensure proper interlock.

- Modern techniques like guide walls and GPS-based systems improve precision.

- Cost:

- Higher initial cost compared to simpler pile systems, but justified by performance and durability.

- Ground Vibrations:

- Drilling can cause vibrations; low-vibration techniques like rotary drilling can mitigate this issue.

Innovations in Secant Pile Technology

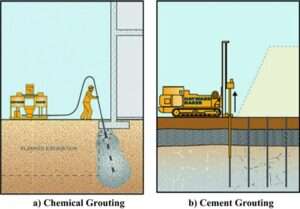

- Cement-Bentonite Slurry:

- Enhances watertightness and improves performance in permeable soils.

- Smart Monitoring Systems:

- Sensors embedded in secant walls provide real-time data on performance, aiding proactive maintenance.

- Sustainable Practices:

- Use of low-carbon concrete and recycled materials reduces environmental impact.

Case Studies

- Deep Excavation in London:

- Secant piles were used to construct a watertight excavation support system for a new subway station.

- Flood Protection in the Netherlands:

- Secant pile walls provided effective groundwater control in a coastal infrastructure project.

Conclusion

Secant piles are a robust and adaptable foundation solution, offering superior excavation support and groundwater control. Their ability to address complex geotechnical challenges ensures stability and safety in demanding construction environments. As innovations continue to enhance their efficiency and sustainability, secant piles will remain a vital tool in modern foundation engineering.