Permeation grouting is a widely used ground improvement technique that involves injecting a fluid grout into soil or rock formations to reduce permeability, stabilize weak soils, and improve overall ground conditions for construction projects. The goal of permeation grouting is to fill the voids and fractures within the ground without altering its structure, thus strengthening the soil, preventing water infiltration, and improving load-bearing capacity. This technique is commonly used in situations where groundwater control, soil stabilization, and protection against erosion or settlement are crucial.

This article explores the process behind permeation grouting, its key benefits, and the various applications in ground engineering.

What is Permeation Grouting?

Permeation grouting is the process of injecting a grout material into the pores and voids of soil or rock formations to reduce their permeability and improve their stability. The grout mixture is typically a liquid that can easily permeate the soil structure, filling voids, fissures, and fractures. As the grout cures, it solidifies, creating a more cohesive and stable soil matrix.

Unlike other types of grouting, such as compaction or jet grouting, permeation grouting does not aim to alter the soil structure significantly or compact the soil. Instead, it seeks to improve the properties of the soil by filling the voids and stabilizing loose or weak soils. Permeation grouting is especially effective for granular soils like sands, gravels, and fractured rock formations.

The grout materials used in permeation grouting typically consist of cement-based mixtures, chemical grouts, or resins. The choice of grout depends on the specific soil conditions, the desired outcome, and the nature of the groundwater conditions.

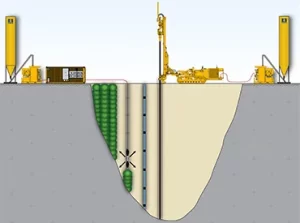

The Permeation Grouting Process

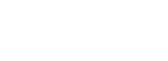

The permeation grouting process involves several steps that ensure the grout is injected effectively and achieves the desired ground improvement. These steps include:

1.Site Assessment and Soil Testing

Before any grouting begins, a thorough geotechnical investigation is conducted to assess the soil’s permeability, composition, and structure. Soil tests, including permeability tests, particle size analysis, and compaction tests, are performed to determine the most appropriate grout material and injection techniques for the project. Understanding the soil characteristics is crucial for selecting the right grout mixture and injection strategy.

2.Grout Preparation

Once the site assessment is completed, the grout mixture is prepared. Cement-based grouts are commonly used for permeation grouting, but in some cases, chemical grouts, such as polyurethane or acrylates, may be chosen depending on the specific application. The grout is typically mixed with water to achieve the desired viscosity, which ensures that it can easily permeate the soil and fill the voids effectively.

3.Grouting Equipment Setup

Specialized equipment is used to inject the grout into the ground. This includes pumps, pressure gauges, and injection pipes or rods, which are placed at strategic locations based on the site conditions. The injection equipment is set up to ensure even distribution of grout throughout the treatment area.

4.Grout Injection

The grout is injected into the ground at a controlled pressure. The injection process is typically done in stages, starting from shallow depths and gradually working deeper as the grout fills the soil voids. The injection pressure is carefully controlled to ensure that the grout permeates the soil without causing over-pressurization or soil displacement.

5.Curing and Monitoring

Once the grout is injected, it undergoes a curing process, which hardens the grout and binds the soil particles together. During the curing process, the grout solidifies and creates a stable matrix within the soil. Engineers monitor the grouting process to ensure that the grout is spreading evenly and filling the targeted voids.

Post-grouting testing may be performed to verify that the desired soil improvements have been achieved. This could include permeability tests, soil strength analysis, and settlement monitoring.

Benefits of Permeation Grouting

Permeation grouting offers a range of benefits, making it a preferred solution for many ground stabilization and groundwater control projects. Some of the key advantages of permeation grouting include:

1.Reduced Permeability

The primary benefit of permeation grouting is its ability to reduce soil permeability, which is crucial for groundwater control and preventing water seepage. By filling voids and fractures in the soil with grout, the flow of water through the ground is significantly reduced, making it ideal for applications where water ingress is a concern.

2.Soil Stabilization

Permeation grouting strengthens weak or loose soils by filling in voids and increasing soil cohesion. This stabilization improves the soil’s load-bearing capacity, making it more suitable for supporting foundations, structures, or embankments.

3.Non-Disruptive Process

Unlike other soil stabilization methods that may require excavation or soil displacement, permeation grouting is relatively non-invasive. The grout is injected into the ground without significantly disturbing the existing soil, which minimizes disruption to the surrounding environment and existing structures.

4.Improved Structural Integrity

By reducing permeability and increasing soil stability, permeation grouting helps to improve the overall integrity of structures built on or within the treated soil. This can prevent issues such as foundation settlement, soil erosion, or water damage.

5.Long-Term Solution

The grout used in permeation grouting solidifies and cures over time, creating a durable and long-lasting improvement in the soil. Once the grout has cured, it provides long-term benefits in terms of reduced permeability, improved stability, and enhanced load-bearing capacity.

6.Cost-Effective

Permeation grouting can be a cost-effective solution for improving soil conditions, particularly when compared to more invasive methods such as soil replacement or deep excavation. The technique can also reduce the need for complex drainage systems, further cutting costs.

7.Versatility

Permeation grouting can be applied to a wide range of soil types, including granular soils like sands and gravels, as well as fractured rock formations. It is effective in both shallow and deep soil layers, making it a versatile solution for various geotechnical challenges.

Applications of Permeation Grouting

Permeation grouting is widely used in a variety of applications within ground engineering, particularly in situations where soil stabilization, groundwater control, and foundation reinforcement are required. Some common applications include:

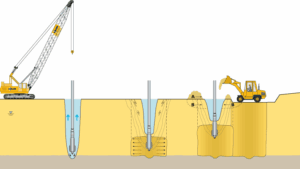

1.Waterproofing and Groundwater Control

Permeation grouting is often used in construction projects where groundwater infiltration is a concern. By reducing soil permeability, permeation grouting prevents water from entering underground spaces, such as tunnels, basements, or foundation pits, and ensures that structures remain dry and stable.

2.Foundation Stabilization

In areas with weak or unstable soils, permeation grouting can improve the strength and stability of the soil, providing a more solid foundation for buildings, bridges, and other infrastructure projects. This technique is particularly effective in areas with high water tables or where soil conditions are less than ideal for construction.

3.Slope Stabilization

Permeation grouting can be used to stabilize slopes and prevent erosion or landslides in areas with loose or sandy soils. By reducing soil permeability and increasing soil cohesion, permeation grouting helps maintain slope stability, particularly in areas prone to heavy rainfall or seismic activity.

4.Soil Liquefaction Mitigation

In earthquake-prone areas, permeation grouting can help mitigate the risk of soil liquefaction, a phenomenon where saturated soils lose their strength during seismic events. By filling the voids in the soil with grout, this technique can reduce the likelihood of liquefaction and improve the soil’s ability to resist seismic forces.

5.Environmental Remediation

Permeation grouting is also used in environmental remediation projects to prevent the spread of contaminants in the ground. The grout can help seal off contaminated areas, preventing the migration of pollutants and protecting groundwater resources from contamination.

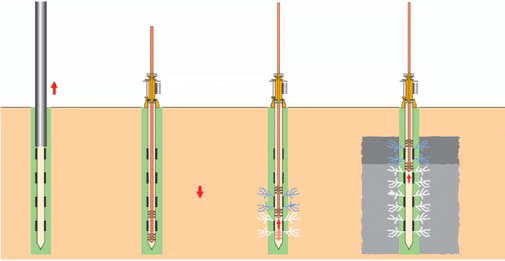

6.Tunneling and Underground Construction

In tunneling and underground construction projects, permeation grouting is commonly used to control water ingress and stabilize the ground. By reducing the permeability of the soil, the grouting process helps ensure that tunnels and underground structures remain dry and safe during construction.

Conclusion

Permeation grouting is a highly effective ground improvement technique that plays a vital role in stabilizing soils, reducing permeability, and preventing water infiltration in construction projects. By filling voids and fractures in the soil with grout, this technique enhances soil strength, improves stability, and provides long-term protection for foundations, slopes, and underground structures. With its versatility, non-disruptive process, and cost-effective nature, permeation grouting remains a valuable tool for geotechnical engineers tackling a wide range of ground engineering challenges.