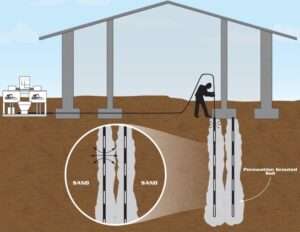

Permeation grouting is a well-established and versatile method employed in geotechnical engineering to improve the mechanical properties of soil or rock and mitigate seepage in underground construction. This technique is particularly valuable for stabilizing granular soils, enhancing load-bearing capacity, and sealing voids to control water flow, making it an essential tool for ground improvement and seepage control.

What is Permeation Grouting?

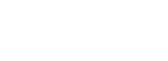

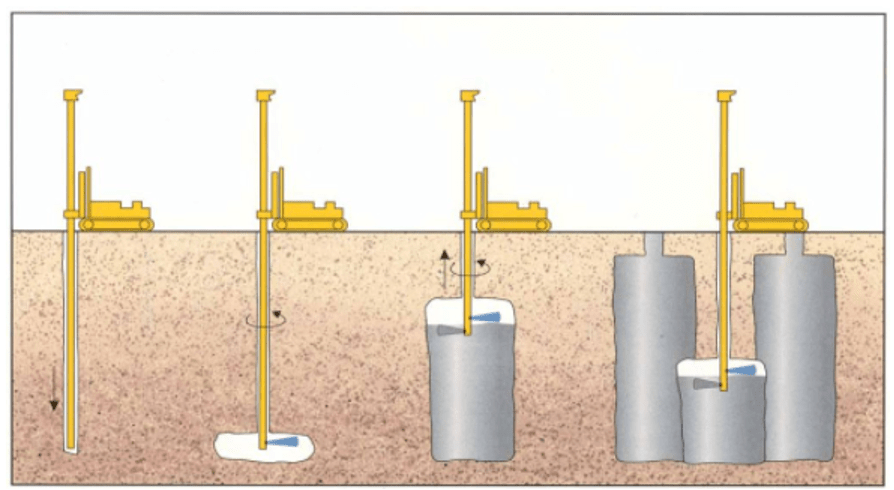

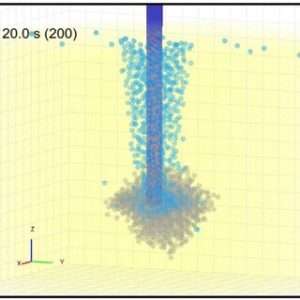

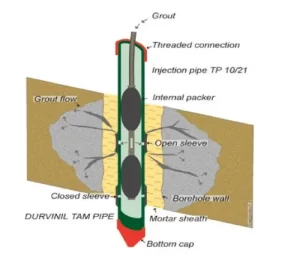

Permeation grouting involves the injection of a fluid grout into the pores of soil or rock without disturbing the existing structure. The grout is typically a low-viscosity material, such as cement-based slurries, silicates, or resins, designed to permeate and fill the voids between soil particles. Once set, the grout creates a solid matrix that enhances the strength and impermeability of the treated material.

Applications of Permeation Grouting

- Seepage Control:

Permeation grouting is extensively used to control water infiltration in tunnels, dams, and below-grade structures. By sealing voids and reducing soil permeability, it prevents groundwater from compromising structural integrity. - Ground Stabilization:

The technique is effective for stabilizing granular soils, improving their load-bearing capacity, and preventing settlement in foundation projects. It is often used in urban areas where adjacent structures need protection from excessive settlement. - Void Filling:

In scenarios involving abandoned pipes, caverns, or voids created by excavation or mining, permeation grouting provides a reliable solution for filling spaces and preventing future collapse. - Infrastructure Repairs:

Grouting enhances the lifespan of aging infrastructure, such as subways, retaining walls, and culverts, by reinforcing the surrounding soil and preventing further degradation.

Benefits of Permeation Grouting

- Non-Disruptive:

This technique can be applied without significantly disturbing the existing ground structure, making it ideal for retrofitting projects in urban or sensitive areas. - Precision Control:

Engineers can precisely control the flow and placement of grout, allowing targeted treatment of problem areas. - Versatility:

A wide range of grout materials and formulations are available to suit various soil conditions and project requirements. - Durability:

The solidified grout matrix provides long-term stability and resistance to environmental factors, such as water erosion or seismic activity.

Challenges and Considerations

While permeation grouting is a powerful tool, it requires careful planning and execution to ensure success:

- Material Selection:

The choice of grout depends on soil type, permeability, and project objectives. Incorrect selection can result in ineffective treatment or excessive costs. - Injection Pressure:

Controlling the injection pressure is critical to avoid fracturing the soil, which can lead to unintended consequences. - Cost:

Although cost-effective compared to alternative methods, permeation grouting can be expensive for large-scale projects due to the materials and equipment involved.

Conclusion

Permeation grouting plays a crucial role in modern construction and geotechnical engineering, offering a reliable solution for improving ground conditions and controlling seepage. Its non-intrusive nature, versatility, and effectiveness make it indispensable for a wide range of projects. As technology advances, innovations in grout materials and injection techniques will further enhance the efficiency and applicability of this vital technique.