In the world of geotechnical engineering, stability is paramount, especially in projects that involve deep excavations, high water tables, or challenging soil conditions. Secant pile walls offer an advanced solution for providing structural support and earth retention, ensuring the stability of both the excavation and surrounding environment. These walls are increasingly employed in complex projects such as tunnel construction, basement excavation, and slope stabilization. With their unique construction process and ability to provide both strength and waterproofing, secant pile walls have become a preferred choice for addressing the toughest geotechnical challenges.

What Are Secant Pile Walls?

A secant pile wall is a type of retaining structure made by drilling overlapping piles into the ground. These piles are typically made of reinforced concrete, and they form a continuous barrier to support deep excavations, prevent soil movement, and control groundwater flow. Unlike tangent piles, where the piles are spaced apart, secant piles overlap, creating a solid, watertight, and structurally sound wall.

Secant pile walls are typically constructed in two phases:

- Primary Piles: These piles are drilled and concreted first, usually made of higher-strength concrete or steel reinforcement.

- Secondary Piles: After the primary piles have set, secondary piles are drilled between them. The secondary piles intersect and overlap the primary piles, forming the continuous, interlocking wall.

Applications of Secant Pile Walls

Secant pile walls are versatile and provide solutions to a wide range of geotechnical challenges. Some of the most common applications include:

Deep Excavations

- Basement Construction: For large-scale basement projects or underground parking structures, secant pile walls are used to retain soil and support excavation depths of several stories.

- Urban Development: In cities with congested environments, secant pile walls are crucial for providing support in tight spaces without causing disturbance to surrounding buildings or infrastructure.

2. Water Control and Waterproofing

- Groundwater Management: Secant pile walls are effective at preventing water ingress, making them ideal for projects below the water table or in areas with high groundwater levels.

- Flood Protection: In flood-prone regions, secant pile walls can be used to create impermeable barriers to protect the site and surrounding areas.

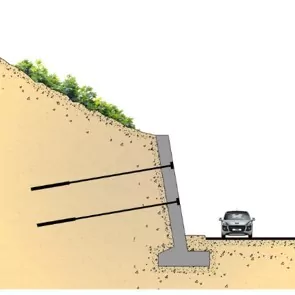

3. Slope Stabilization

- Preventing Landslides: In hilly or mountainous areas, secant pile walls are often used to stabilize slopes and prevent soil erosion or landslides.

- Reinforcing Embankments: These walls can be installed along embankments to ensure their structural integrity and prevent soil movement.

4. Tunnels and Underground Infrastructure

- Cut-and-Cover Tunnels: Secant pile walls are widely used in the construction of cut-and-cover tunnels, where deep excavations need to be supported during tunnel construction.

- Underground Utility Systems: For projects requiring extensive underground infrastructure, secant pile walls provide the necessary stability and safety during excavation.

Advantages of Secant Pile Walls

1. Structural Strength and Stability

- The interlocking design of secant pile walls provides superior strength compared to other types of pile walls. The overlapping piles form a solid barrier, preventing soil movement and ensuring stability in deep excavations.

- The continuous nature of the wall makes it an ideal solution for sites requiring high load-bearing capacities or significant lateral support.

2. Waterproofing Capabilities

- One of the key advantages of secant pile walls is their ability to provide a waterproof barrier. The overlapping piles seal the gaps between them, making it extremely difficult for water to penetrate. This makes secant pile walls particularly effective in environments with high groundwater levels or where water management is critical.

- The waterproofing properties are especially valuable in applications like underground structures, tunnels, and foundations in flood-prone areas.

3. Adaptability to Complex Soil Conditions

- Secant pile walls are highly effective in complex geotechnical conditions, such as areas with loose or soft soils, high water tables, or fractured rock. The flexibility in design allows secant pile walls to be tailored to a wide range of soil conditions, making them suitable for diverse projects.

- The drilling process allows secant piles to penetrate challenging soil types and reach deeper, more stable strata, ensuring that the foundation remains secure.

4. Minimized Vibration and Noise

- Compared to driven pile systems, secant pile walls generate minimal vibration and noise during installation. This is a significant advantage in urban areas, where nearby structures may be sensitive to vibration or noise disruptions.

- This non-disruptive installation method also makes secant pile walls ideal for projects that need to preserve the surrounding environment, such as historical buildings or sensitive infrastructure.

5. Long-Term Durability

- Secant pile walls are highly durable and designed to withstand the test of time. Made of reinforced concrete, they are resistant to environmental factors such as soil corrosion, water, and chemical reactions. This ensures that they remain functional and stable throughout the lifespan of the structure they support.

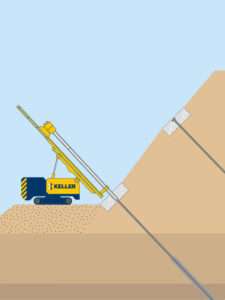

Installation Process for Secant Pile Walls

The installation of a secant pile wall generally follows these steps:

1. Site Preparation: The excavation area is prepared by clearing the site, installing safety measures, and identifying the layout for the pile wall.

2. Primary Pile Installation: Primary piles are drilled into the ground using a rotary drilling rig. These piles are typically reinforced with steel and poured with high-strength concrete.

3. Secondary Pile Installation: After the primary piles are in place, secondary piles are drilled between them. The secondary piles are designed to overlap the primary piles to create a continuous, interlocking wall.

4. Grouting and Curing: Grouting is injected into the gaps between the piles to improve the wall’s structural integrity and waterproofing properties. The grout ensures a strong bond between the piles and the surrounding soil.

5. Wall Cutting and Leveling: The tops of the piles are cut and leveled to the required height, ensuring that the secant pile wall is uniform and aligned.

6. Final Backfilling and Finishing: Any remaining excavation is backfilled, and additional waterproofing systems or drainage may be added if required.

Challenges and Considerations

While secant pile walls offer significant advantages, there are a few challenges to consider:

1. Cost:

Secant pile walls are generally more expensive than other pile wall systems, primarily due to the labor-intensive process of drilling and grouting the piles. However, the long-term benefits, such as enhanced stability and waterproofing, often justify the higher initial costs.

2. Soil Conditions:

The installation of secant pile walls requires specialized equipment and skilled labor. Complex soil conditions, such as mixed layers of soft and hard ground, can complicate the drilling process and increase installation time.

3. Site Access:

Secant pile walls require access for large drilling rigs and other equipment. In areas with limited access or densely built environments, the installation process may be more challenging.

Conclusion

Secant pile walls are an indispensable tool in modern geotechnical engineering, providing exceptional stability, earth retention, and waterproofing in complex projects. Their ability to withstand high loads, resist water ingress, and adapt to a variety of soil conditions makes them a reliable choice for challenging excavation sites. From urban construction to tunnel and slope stabilization, secant pile walls ensure that deep, difficult projects are completed with safety and precision. As technology and materials continue to evolve, secant pile walls will remain a cornerstone of geotechnical solutions, offering unparalleled support for the foundation of modern infrastructure.