Introduction

Consolidation grouting is a widely used ground improvement technique designed to increase the strength, stiffness, and load-bearing capacity of soil and rock formations. By injecting grout into loose or weak ground, engineers can reduce settlement, enhance foundation stability, and improve overall structural integrity. This technique is commonly used in dam foundations, tunnels, deep excavations, and large infrastructure projects where stable ground conditions are essential.

1.Understanding Consolidation Grouting

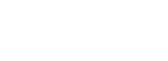

Consolidation grouting, also known as compaction grouting, involves injecting low-mobility grout into the soil or rock under controlled pressure. Unlike permeation grouting, which fills pore spaces, consolidation grouting displaces and compacts the surrounding material, increasing its density and load-bearing capacity.

Key Components of Consolidation Grouting:

- Low-Mobility Grout – Typically a thick cementitious or soil-based mixture to provide structural support.

- Injection Boreholes – Drilled strategically to reach weak zones and optimize grout distribution.

- Controlled Pressure Injection – Ensures grout does not migrate beyond the target area, preventing excessive soil displacement.

2.Applications of Consolidation Grouting

Consolidation grouting is widely used in geotechnical and foundation engineering for:

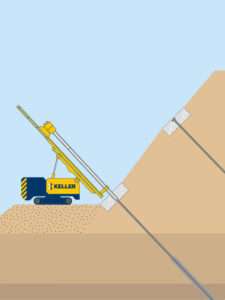

- Foundation Strengthening – Improves soil stability beneath buildings, bridges, and highways.

- Dam and Embankment Reinforcement – Prevents seepage and strengthens foundation materials.

- Settlement Control – Reduces excessive ground settlement in weak or compressible soils.

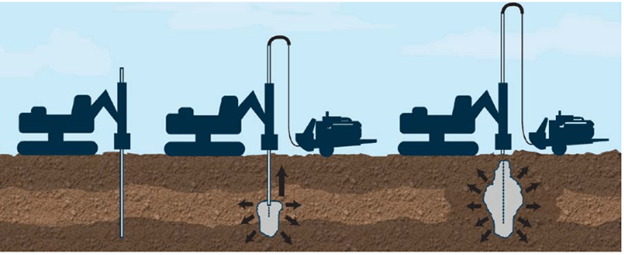

- Tunnel and Underground Construction – Enhances ground support and minimizes excavation risks.

- Slope and Landslide Stabilization – Increases cohesion and prevents soil failure.

3.Types of Grout Used in Consolidation Grouting

The choice of grout depends on soil conditions and project requirements:

- Cement-Based Grout – Ideal for coarse-grained soils and fractured rock formations.

- Fly Ash and Bentonite Mixtures – Used to improve flowability and reduce permeability.

- Chemical Grout – Expanding resins or silicates for soil reinforcement and waterproofing.

4.Advantages of Consolidation Grouting

Increases Load-Bearing Capacity – Essential for supporting heavy structures.

Reduces Settlement Risks – Prevents long-term foundation movement.

Improves Ground Stability – Strengthens weak soils and rock formations.

Minimally Invasive – Requires minimal excavation and site disruption.

Customizable for Different Soil Types – Works in granular, cohesive, and mixed soils.

5.Challenges and Considerations

Requires Precise Grouting Techniques – Poor execution can cause uneven soil strengthening.

Potential Soil Displacement Issues – Excessive pressure can lead to unintended ground movement.

Variable Soil Conditions – Different soils require tailored grout formulations and injection strategies.

6.Innovations in Consolidation Grouting

- Automated Injection Systems – Improve precision and consistency.

- Smart Grout Monitoring Sensors – Provide real-time data for optimized performance.

- Eco-Friendly Grouting Materials – Reduce environmental impact while maintaining efficiency.

Conclusion

Consolidation grouting is a vital geotechnical technique for enhancing foundation stability, improving soil properties, and reducing settlement risks. By selecting the appropriate grout material and applying advanced injection methods, engineers can ensure long-term durability and structural safety in a wide range of construction projects. With ongoing advancements in technology and materials, consolidation grouting continues to be an essential tool for modern ground engineering.