Introduction

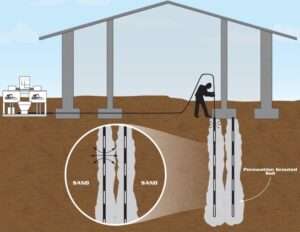

Rock fissure grouting is a specialized ground improvement technique used to seal cracks, fractures, and voids in rock masses. This method enhances the structural integrity of rock formations, reduces water seepage, and prevents ground instability in tunnels, dams, and deep excavations. By injecting grout under controlled pressure, engineers can reinforce weak rock zones, minimize permeability, and improve load-bearing capacity.

1.Understanding Rock Fissure Grouting

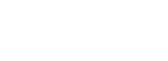

Rock fissure grouting involves injecting a cementitious, chemical, or resin-based grout into fractured rock to fill voids and bind loose particles. This process stabilizes rock formations and prevents water infiltration, making it essential in projects requiring secure underground conditions.

Key Components of Rock Fissure Grouting:

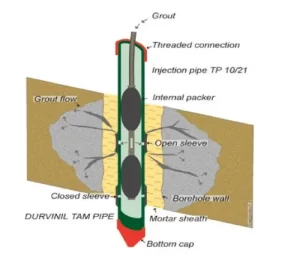

- Grout Material – Selected based on rock type, permeability, and project requirements.

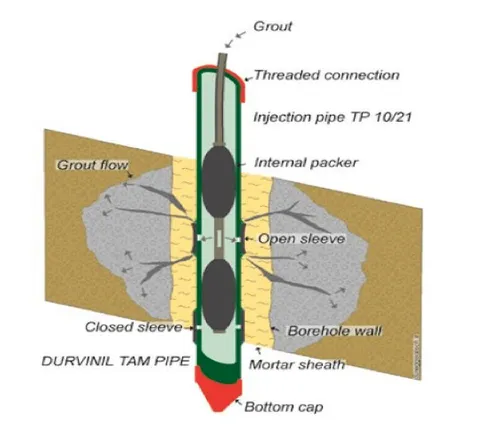

- Injection Boreholes – Drilled to access fissures and optimize grout penetration.

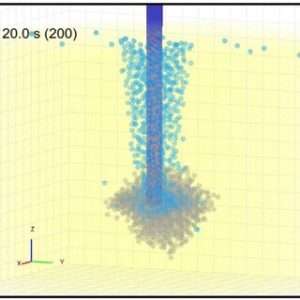

- Controlled Pressure Injection – Ensures grout fills cracks effectively without causing additional fractures.

2.Applications of Rock Fissure Grouting

Rock fissure grouting is widely used in various geotechnical and infrastructure projects:

- Tunnel Construction – Strengthens rock formations and prevents water inflow.

- Dam Foundations – Reduces seepage and reinforces rock stability.

- Slope Stabilization – Prevents rockfalls and improves mass cohesion.

- Mine and Underground Caverns – Seals cracks to enhance structural safety.

- Bridge and Highway Foundations – Improves bearing capacity in fractured rock.

3.Types of Grout Used in Rock Fissure Grouting

Different grouting materials are selected based on project needs and rock conditions:

- Cement-Based Grout – Ideal for large fissures and improving rock mass stability.

- Chemical Grout – Polyurethane, silicate, or epoxy-based solutions for waterproofing and fine crack sealing.

- Microfine Cement Grout – Allows deeper penetration into narrow rock fractures.

- Resin-Based Grout – Expanding materials for sealing and reinforcing fractured zones.

4.Advantages of Rock Fissure Grouting

Seals Rock Cracks and Voids – Prevents water leakage and soil erosion.

Enhances Structural Integrity – Strengthens rock formations for long-term stability.

Reduces Groundwater Seepage – Essential for tunnels, dams, and basements.

Customizable Grouting Solutions – Various grout materials for different rock types.

Minimal Surface Disturbance – No need for large-scale excavation.

5.Challenges and Considerations

Requires Accurate Site Investigation – Identifying fissure patterns is crucial for effective grouting.

Variable Rock Permeability – Some rock types may require specialized grout formulations.

Pressure Control is Essential – Excessive pressure can widen cracks instead of sealing them.

6.Innovations in Rock Fissure Grouting

- Real-Time Grout Flow Monitoring – Enhances accuracy and efficiency.

- Eco-Friendly Grouting Materials – Reduces environmental impact.

- Automated Injection Systems – Improves consistency in large-scale projects.

Conclusion

Rock fissure grouting is a critical technique for sealing and reinforcing fractured rock masses, ensuring the stability of underground structures, slopes, and foundations. By using advanced grout materials and injection technologies, engineers can effectively control groundwater flow, enhance rock strength, and extend the lifespan of infrastructure. As geotechnical innovations continue, rock fissure grouting will play an even greater role in modern construction and engineering.