Introduction

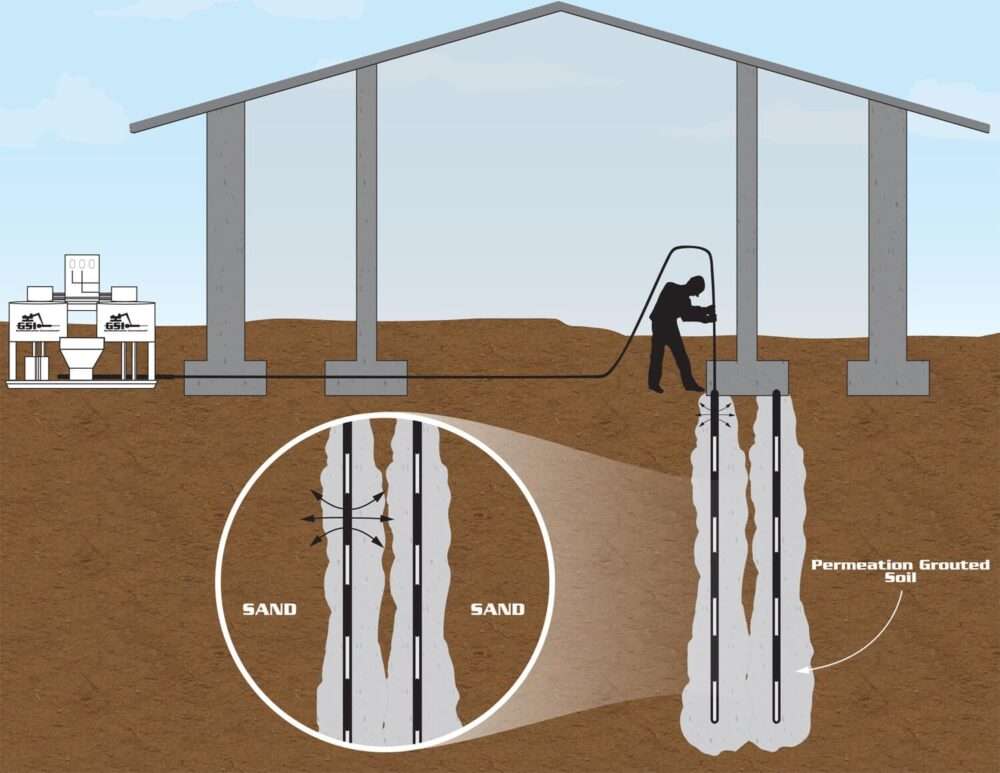

Permeation grouting is a specialized ground improvement technique used to enhance soil strength, reduce permeability, and control groundwater flow. This method involves injecting grout into porous soils or fractured rock to fill voids and bind particles without significantly altering the soil structure. It is widely used in construction, tunneling, and foundation engineering to reinforce weak soils and prevent water infiltration.

1.Understanding Permeation Grouting

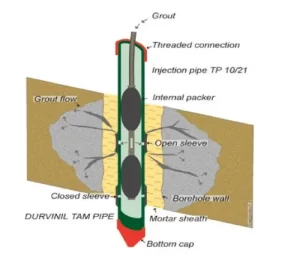

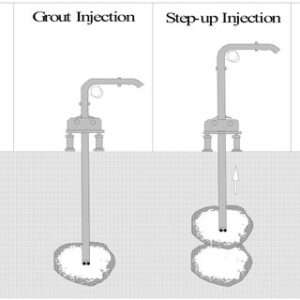

Permeation grouting, also known as pressure grouting, involves the injection of low-viscosity grout into the soil under controlled pressure. The grout spreads through the pore spaces, solidifying the ground while maintaining its original structure. This method is ideal for granular soils, such as sands and silts, where it can effectively improve stability and water resistance.

Key Components of Permeation Grouting:

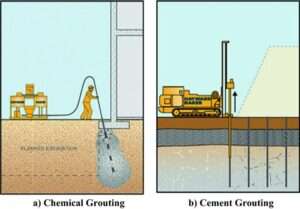

- Grout Material – Cement-based, chemical, or polymer-based grout is selected based on soil conditions and project requirements.

- Injection System – A network of pipes or injection points ensures even distribution.

- Pressure Control – Controlled injection pressure prevents soil displacement.

2.Applications of Permeation Grouting

Permeation grouting is used in various geotechnical and construction applications:

- Foundation Strengthening – Enhances soil bearing capacity for buildings and structures.

- Seepage Control in Excavations – Prevents groundwater inflow in basements, tunnels, and shafts.

- Underground Infrastructure Protection – Reinforces soil around utilities and pipelines.

- Cavity and Void Filling – Stabilizes loose soils and fills underground voids.

- Slope and Embankment Stabilization – Reduces erosion and increases slope stability.

3.Types of Grout Used in Permeation Grouting

The choice of grout depends on the soil conditions and project goals:

- Cementitious Grout – Common for sandy soils and structural reinforcement.

- Chemical Grout – Polyurethane, silicate, or acrylate-based grouts for waterproofing and fine-grain soil treatment.

- Resin-Based Grout – Expanding polymers for sealing cracks and voids in rock formations.

4.Advantages of Permeation Grouting

Improves Soil Strength Without Excavation – No need for major earthworks.

Effective Groundwater Control – Reduces seepage in underground structures.

Minimal Disruption – Ideal for projects in urban or confined areas.

Versatile Application – Works in various soil conditions and project scales.

Durability and Long-Term Stability – Provides lasting ground reinforcement.

5.Challenges and Considerations

Not Effective in Clayey Soils – Limited penetration in fine-grained or low-permeability soils.

Requires Precision in Injection Control – Poor control can lead to uneven treatment.

Chemical Grouting Costs – Certain grout materials can be expensive.

6.Innovations in Permeation Grouting

- Automated Grout Injection Systems – Enhance accuracy and efficiency.

- Advanced Monitoring with Sensors – Real-time data for improved control.

- Eco-Friendly Grouting Materials – Sustainable alternatives to reduce environmental impact.

Conclusion

Permeation grouting is a reliable technique for soil stabilization, foundation reinforcement, and groundwater control. Its ability to improve weak soils and reduce permeability makes it a valuable solution for complex geotechnical challenges. With continued advancements in materials and injection technology, permeation grouting is set to become even more efficient and environmentally friendly in modern construction.